Speaking of stone processing, people always think of heavy, stupid, rough, noisy. Nowadays, in the stone industry, through the joint efforts of government, industry, university and research parties, the "line saw" equipment is gradually popularized, replacing the original "saw and cut" process, setting off a stone processing technology revolution, and solving the "three high" problems of high consumables, high noise and high waste on the road of industrial intelligent manufacturing upgrading.

"Line" instead of "saw" to achieve technological iterative change

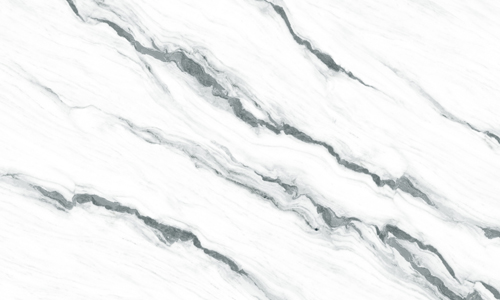

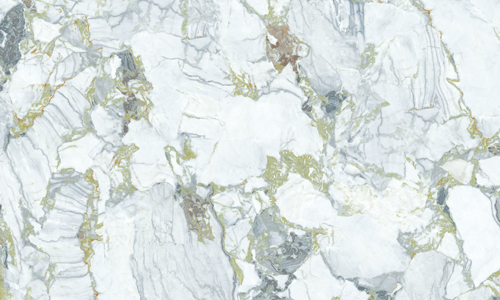

With the continuous promotion of wire saw production equipment, the replacement speed has gradually increased. The advantage of line saw is very obvious. Previously, the slit width of the traditional stone bridge saw to four or five millimeters, not only brings a great waste of raw stone, if the stone has cracks, there is also a very high risk of the whole stone collapse, the resulting amount of waste slag and the later cleanup costs are also rising. In addition, the noise generated by the traditional combination saw is as high as 130 decibels or more, and you can't hear it when talking face to face, which is very unfavorable to the safe operation of employees. Now the line saw equipment, processing capacity has been able to meet 30% of the production capacity. The sound of the new equipment, which is 25 meters high, is only similar to the sound of a stream, and the marble gap cut by the diamond wire is only about 0.4 mm.

Taking high-end marble as an example, after the equipment is updated, the material yield per cubic meter plate (ordinary 1.75 cm thickness) can be increased by more than 15%, only from the "stone joint" can be more "output" hundreds of thousands of yuan, coupled with the loss of other links, the benefit is obvious. According to estimates, the cutting joint of the new equipment can be reduced to 0.5 to 0.7 mm, which can reduce the stone powder generated by processing by 85-90%, and the thickness of the processed sheet can be as thin as 3 to 5 mm, achieving light transmission development, increasing the output rate by more than 15%, and reducing the noise during processing to below 100 decibels.

The wire saw equipment manufacturing industry has gradually become a cluster

"Wire saw" technology is not out of thin air, the technology was originally used in the photovoltaic industry to cut magnets, a few years ago, because of the industry's own upgrade needs, this technology began to cross the boundary into the stone processing ranks. In order to crack the dilemma of "heavy and stupid" processing of stone materials, the increasingly mature line saw equipment has gradually entered the industry's sight. The equipment size has changed from small to large, and the diamond line has also changed from short to long, and after continuous run-in and upgrading, enterprises have begun to accept money saw equipment. This is inseparable from the promotion and guidance of local governments and subsidy support. After the high-standard equipment has been put into operation, the enterprise can achieve an annual processing volume of 400,000 square meters, and ranks among the top enterprises in the processing of raw stone.

It is worth mentioning that with the increase in demand for equipment, a number of wire saw equipment manufacturing enterprises actively entered the game. According to incomplete statistics, at present, only in Shuitou, China, has been active dozens of large and small wire saw equipment manufacturing companies sales and service organizations, and this number is still growing. Still taking Shuitou Town as an example, conservative according to the number of 300 companies, each two equipment, the current distance from saturation there is at least 500 space, the total market value of more than 100 million yuan. Under the guidance of the government, we will further encourage both supply and demand to enter the market and promote industrial upgrading.

Still need to optimize: research common demand continues to upgrade the industrial chain

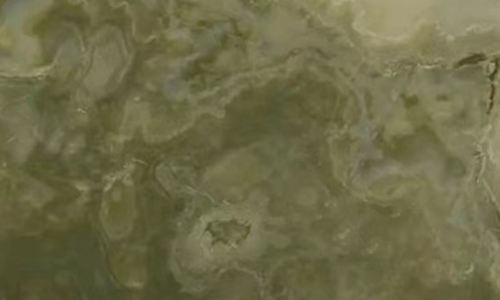

Technological innovation is not achieved overnight and requires continuous innovation and optimization. Although the current line saw equipment has many benefits, most of it is still only suitable for cutting marble and luxury stone with less hardness, and in the face of "hard stones" such as granite, it is still powerless.

How to attract more high-quality enterprises to land the equipment manufacturing industry and strengthen the industrial chain? How to find the common needs of stone processing enterprises for technology upgrading from the demand side, continue to output innovative technology, and optimize line saw equipment?

Suočeni s prijedlozima za nadogradnju tehnologije zelene i inteligentne industrije kamena, kako bi se dodatno konsolidirao i poboljšao učinak primjene "line saw" tehnologije, više odjela i jedinica društva surađivalo je i održalo ključne zajedničke aktivnosti istraživanja tehnologije "horse racing" u industriji kamena. Usredotočite se na "bolne točke" i "poteškoće" industrije, objavite ključne zajedničke tehničke potrebe istraživanja i zajednički se pozabavite ključnim problemima. Organizirajte stručne timove u institucije za proizvodnju opreme kako biste potražili stvarne poteškoće tehnoloških prodora, a zatim kroz mehanizam "horse racingd", usmjerite resurse svih strana da zajednički pronađu rješenja problema, dugo vremena za rad i traže bolju nadogradnju predložak za visokokvalitetni razvoj tehnološke obrade kamene industrije.

O nama

Jessie

Fortune East Stone

📧 E-pošta: sales08@fortunestone.cn

📞 Telefon: +86 15880261993

🌐 Web stranice: www.festonegallery.com |www.fortuneeaststone.com